Fumed Silica

-

Model No: HJSIL® 150/200/300/380 USD 4

-

-

-

-

-

-

-

Hydrophilic

-

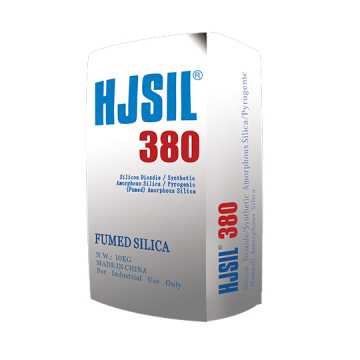

Model No: HJSIL 380 USD 4

-

-

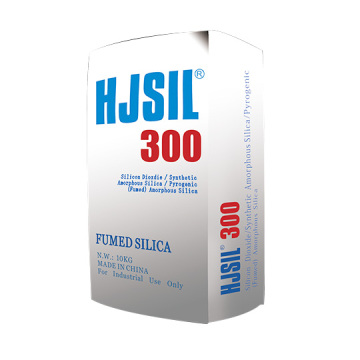

Model No: HJSIL 300 USD 4

-

-

Model No: HJSIL 380 USD 4

-

-

Model No: HJSIL 200 USD 4

-

Hydrophobic

Here you can find the related products in Fumed Silica, we are professional manufacturer of Fumed Silica,Micro Silica,Aerosil Fumed Silica,Aerosil Silica. We focused on international export product development, production and sales. We have improved quality control processes of Fumed Silica to ensure each export qualified product.

If you want to know more about the products in Fumed Silica, please click the product details to view parameters, models, pictures, prices and other information about Fumed Silica,Micro Silica,Aerosil Fumed Silica,Aerosil Silica.

Whatever you are a group or individual, we will do our best to provide you with accurate and comprehensive message about Fumed Silica!

If you want to know more about the products in Fumed Silica, please click the product details to view parameters, models, pictures, prices and other information about Fumed Silica,Micro Silica,Aerosil Fumed Silica,Aerosil Silica.

Whatever you are a group or individual, we will do our best to provide you with accurate and comprehensive message about Fumed Silica!

WHAT IS FUMED SILICA?

Fumed silica, also known as silica fume or pyrogenic silica, is a fine particulate form of silicon dioxide. It is produced by burning silicon tetrachloride in a hydrogen-oxygen flame at very high temperatures. The resulting silica particles fuse together to form a three-dimensional network of extremely fine, spherical particles, which gives fumed silica its characteristic fluffy appearance. Fumed silica is a versatile material with a wide range of industrial applications, including in adhesives, sealants, coatings, composites, cosmetics, pharmaceuticals, and food products. Its unique properties make it a valuable additive for enhancing various physical and performance characteristics in diverse formulations.

-

8000 TonsFumed silica

-

10000 TonsAluminum processing

-

6000 TonsAdhesives and sealants

-

10000 TonsMachining ability